Sensorization &

Data Analytics

Meric Wave’s expertise in sensorization ensures that your operations are equipped with the right tools to gather actionable insights. Our offerings include tailored sensor solutions designed to meet the unique demands of your industry, deployment and sensor fusion to seamlessly integrate multiple sensor types for unified data streams, acquisition of high-quality data, ensuring accuracy and reliability, and real-time monitoring and streaming with instant access to vital data for decision-making. With sensorization at the core of your processes, we transform data into a powerful resource that drives efficiency and innovation.

Why Us?

Proven impact

Comprehensive expertise

From integrating sensors to deploying AI/ML solutions, we provide end-to-end services that address your unique challenges and align with your strategic goals.

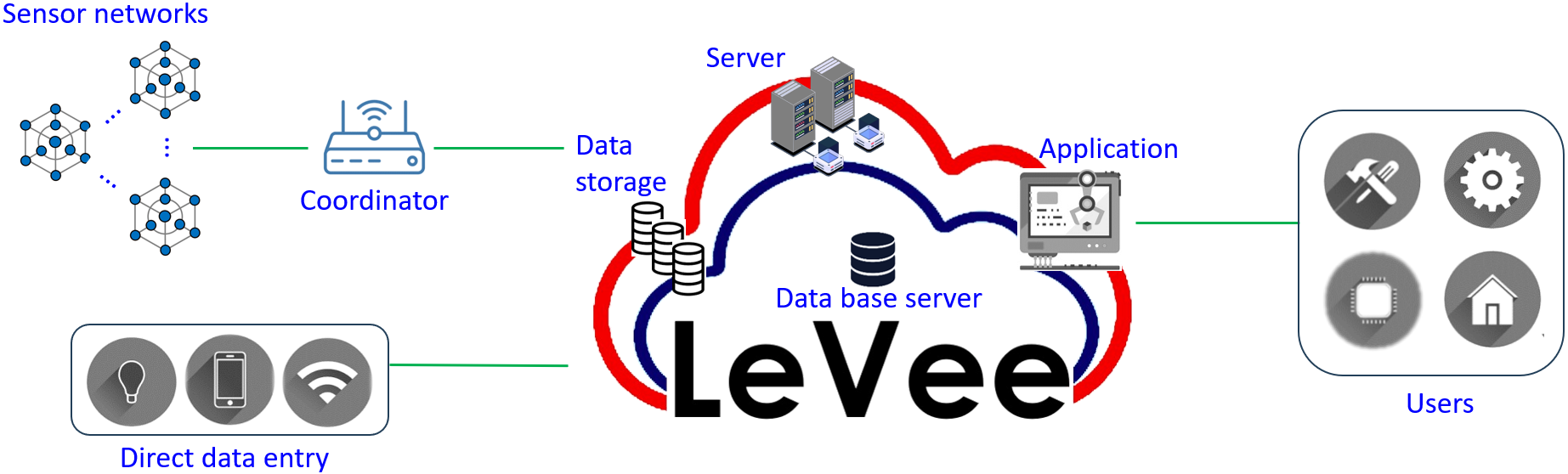

LeVee: Our Cloud Platform

We harness the power of sensorization and real-time data management through LeVee, our robust cloud platform. Designed to seamlessly integrate with sensor networks, LeVee efficiently collects, stores, and processes data from diverse industrial environments.

LeVee bridges the gap between raw sensor data and intelligent decision-making, empowering businesses to optimize operations and enhance productivity.

User-Centric Solutions

Offers intuitive interfaces and customized tools for a wide range of industries, from manufacturing to energy-intensive processes.

Scalable Sensor Integration

Supports dynamic networks of sensors, ensuring adaptability to complex industrial systems.

Centralized Data Management

Stores and organizes data in a secure, cloud-based server, facilitating easy access and analysis.

Custom Solutions

Delivers tailored applications for monitoring, control, and process optimization, ensuring that data is actionable.

Predictive Maintenance

With predictive maintenance, we help industries move from reactive repairs to proactive management. By leveraging sensor data and AI models, we identify early warning signs of equipment failure, allowing businesses to address potential issues before they escalate. For instance, in energy plants, sensors monitor parameters like temperature, pressure, and vibration within combustion systems. By analyzing this data, AI models detect subtle deviations that indicate wear or inefficiencies, helping operators schedule precise maintenance activities. This approach not only minimizes unplanned downtime by up to 40% but also lowers maintenance costs significantly, delivering consistent operational reliability.

Quality Control and Assurance

Sensorization plays a vital role in quality assurance, enabling real-time monitoring and automated detection of defects in production processes. By combining sensor data with AI-driven analytics, we help businesses uphold the highest quality standards. For example, in HVAC system manufacturing, sensors track variables like temperature, humidity, and airflow throughout the production process. AI algorithms analyze this data to detect inconsistencies, such as deviations that could compromise system performance, allowing immediate corrections. This not only reduces material waste by approximately 15% but also ensures final products meet stringent quality benchmarks.

Process Optimization

By integrating real-time data streams with machine learning algorithms, we optimize complex processes to maximize efficiency and minimize waste. Whether in energy-intensive industries like chemical processing or renewable energy systems, our solutions enable businesses to streamline operations and reduce costs. In combustion systems, for example, ML models continuously evaluate fuel flow, temperature, and pressure data, making real-time adjustments to maintain peak performance. This leads to fuel savings of up to 15% and significant reductions in emissions, supporting both financial and environmental objectives.

Comprehensive

Machine Learning

Approach

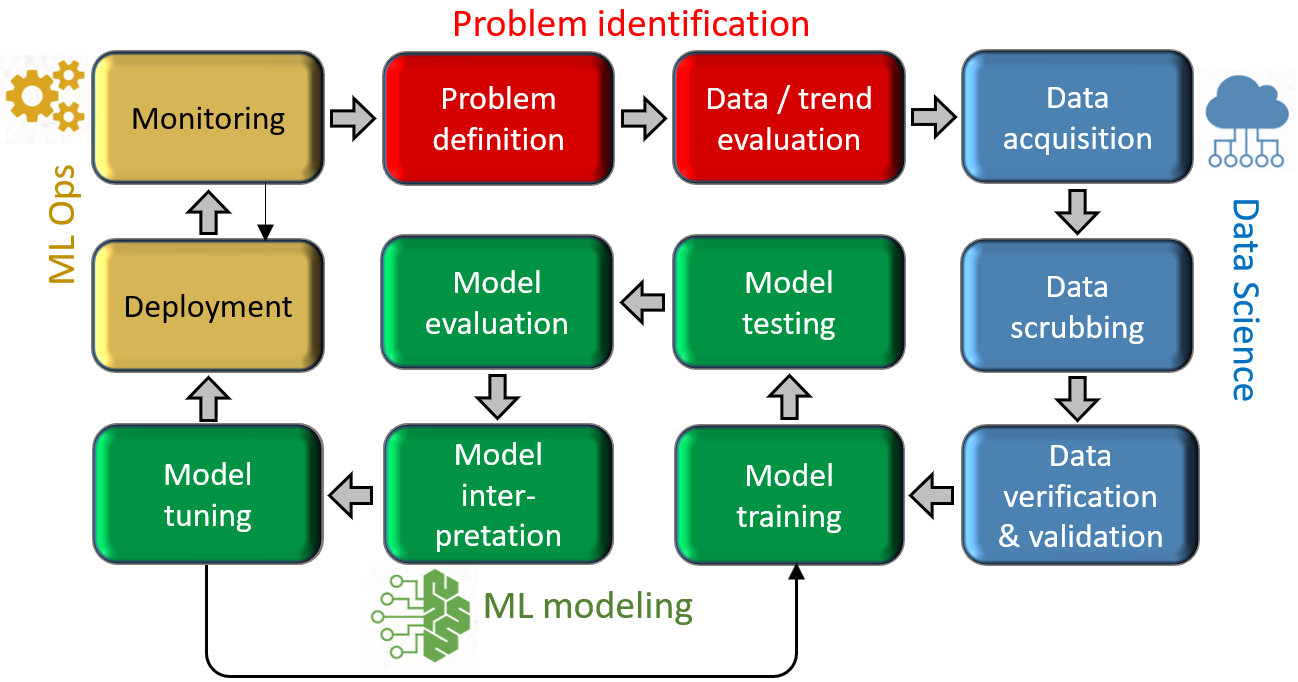

Our machine learning approach is designed to address real-world challenges and deliver maximum value to users across diverse industries. By combining data science, ML modeling, and MLOps into a cohesive workflow, we ensure a robust, scalable, and adaptive system that enhances decision-making and operational efficiency.

Precision Problem-Solving

Structured process begins with clear problem identification through data evaluation and trend analysis. This ensures that the solutions we develop are laser-focused on addressing specific challenges faced by our clients.

Data-Driven Insights

Through meticulous data acquisition, scrubbing, and validation, we transform raw datasets into reliable inputs. This ensures that our ML models are built on high-quality data, leading to accurate and actionable insights.

Customizable ML Models

Our iterative ML modeling process, including training, testing, and evaluation, develop models tailored to unique operational needs. These models uncover hidden patterns, predict trends, and provide actionable recommendations.

Seamless Integration and Deployment

By leveraging MLOps, models become not just theoretical but practical. Deployment is smooth, and continuous monitoring and tuning guarantee long-term relevance and efficiency, even as user needs evolve.

Real-World Applications

Predict energy consumption trends, identify wastage, and enhance sustainability initiatives. in energy field, and improve fleet maintenance schedules and fuel efficiency through predictive analytics. in maritime sector are a few examples.