Simulations & Digital Twins

Meric Wave specializes in providing cutting-edge simulation and digital twin solutions to a wide range of industries. Our services leverage advanced computational tools and expertise to model, simulate, and optimize processes, products, and systems. By integrating simulation-driven insights and real-time digital twins, we help businesses reduce costs, improve efficiency, and accelerate innovation.

Driving Precision and Sustainability

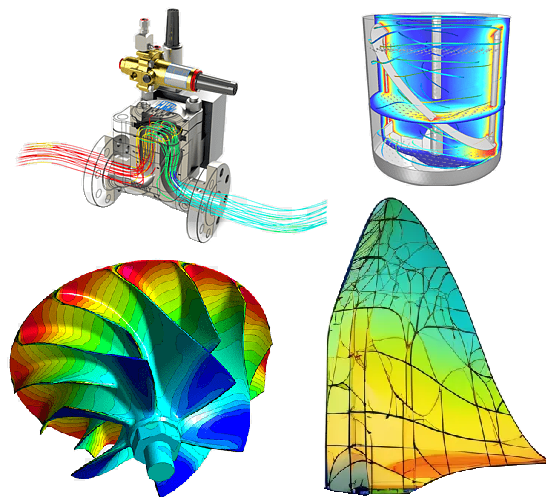

High-Fidelity Simulations

Our comprehensive expertise across diverse sectors including aquaculture, aerospace, maritime, electronics, chemical, biomedical, energy, and beyond tackle industry-specific challenges. By combining advanced virtual engineering capabilities, we deliver solutions tailored to real-world complexities. Our work spans scales from microscale components to full-scale systems, utilizing deterministic, stochastic, and hybrid methodologies. Powered by cutting-edge techniques like finite element analysis, finite volume method, and molecular dynamics, we drive design optimization, predictive insights, cost efficiency, and sustainable outcomes.

House of Competence

Reference Projects

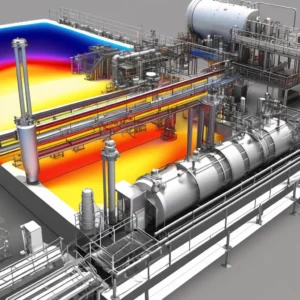

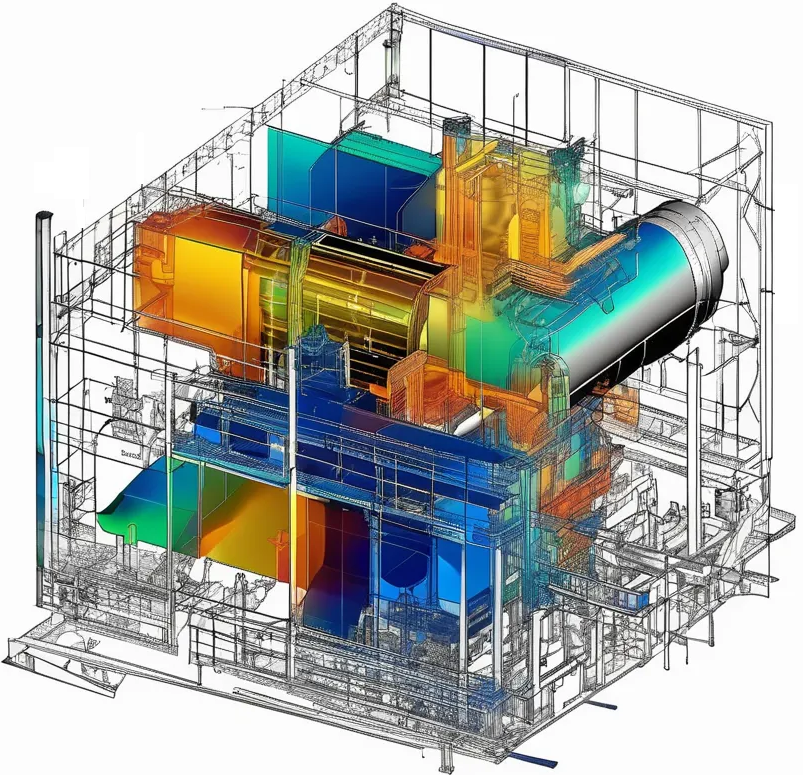

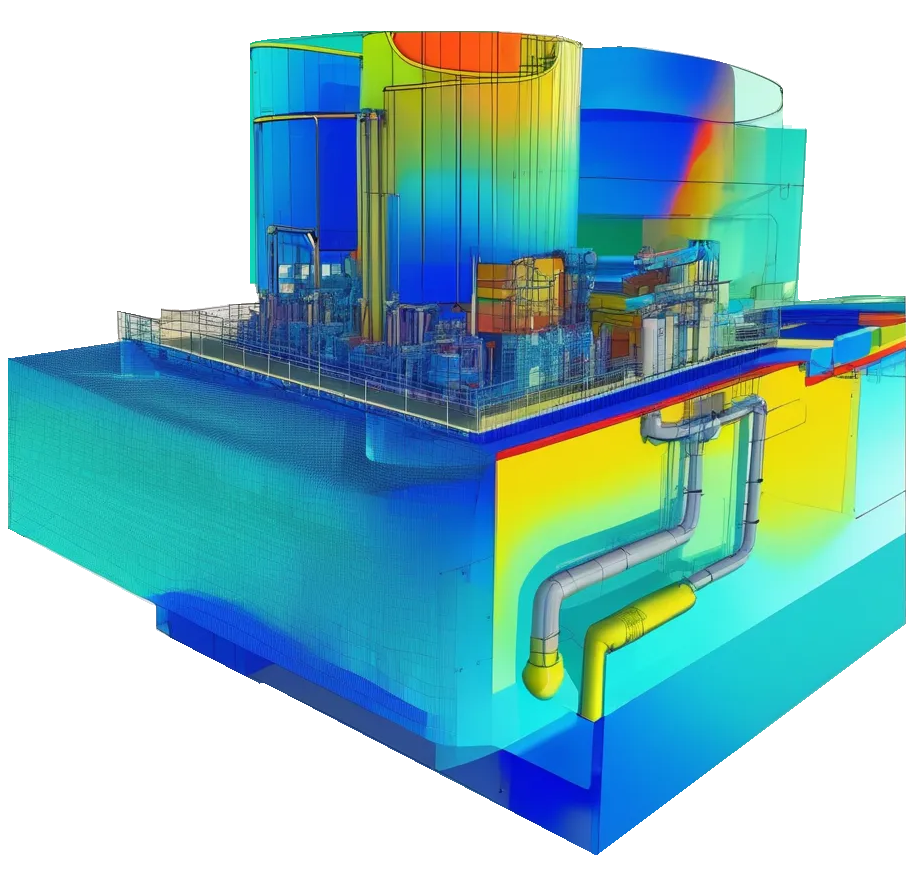

Thermal

Cutting-edge thermal analysis of a chemical plant provides data-driven insights to empower operational efficiency. By identifying heat distributions, safety can be enhanced and emissions can be reduced – driving sustainable progress in energy-intensive industries.

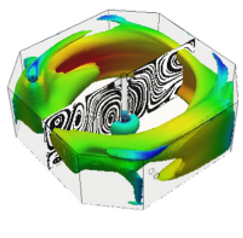

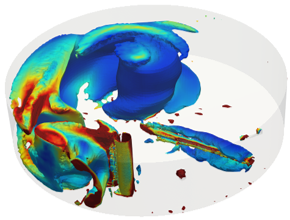

Aquaculture

Ensure sustainable and profitable aquaculture operations by optimizing fish health, feed efficiency, and environmental impact through precise water quality control, predictive maintenance, and intelligent farming practices.

Filtration

Behavior of fluid flow and particle separation within a filtration system to predict the efficiency of foreign matter capture and clogging behavior. This is crucial for designing high-performance filtration systems in industries, ensuring dynamic maintenance scheduling and reduced operational costs.

Aquaculture

Captures complex turbulence patterns in a RAS tank, providing detailed insights into water flow dynamics such as high and low turbulence, which are critical for optimizing oxygen distribution, waste removal, and fish welfare. Design efficient and sustainable aquaculture systems, ensuring healthier aquatic environments and improved operational efficiency.

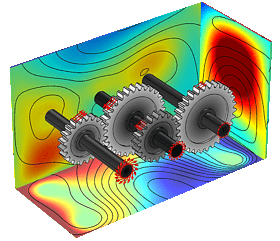

Motion Control

Precision in motion through finite element analysis, enabling a deeper understanding of performance under operational conditions. By integrating simulations with advanced data analytics, identify critical stress points and optimize the design to ensure durability and efficiency.

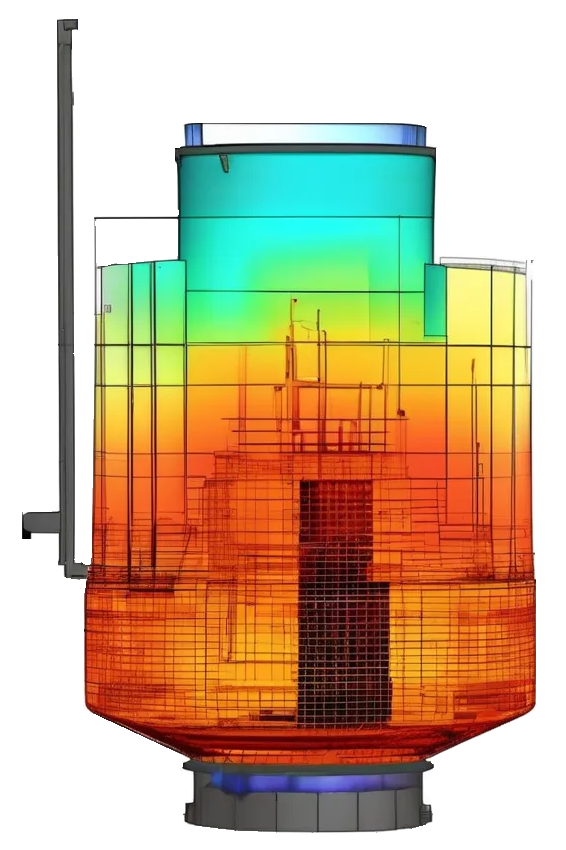

Chemical

Discover the transformative power of multiphysics simulations to identify critical components in your industrial system requiring design reconsideration to enhance safety and performance. By simulating the interplay between thermal, structural, and fluid dynamics, elevate your design process with data-driven optimization today.

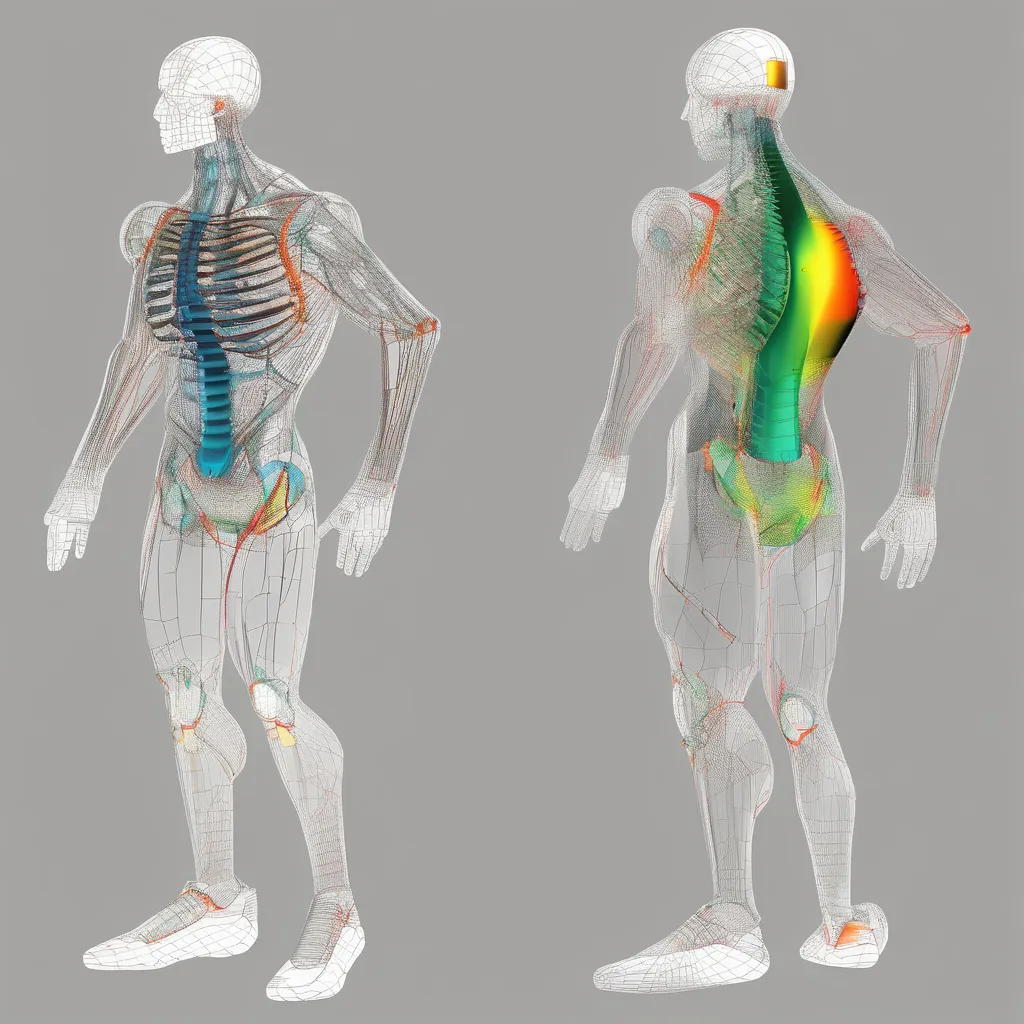

Medical

Revolutionize healthcare and sports performance by creating realistic human models, analyzing biomechanical data, and developing innovative medical devices and training equipment.

Industrial

Obtain precise insights into complex systems for optimized performance and enhanced safety through a coupled structural-thermal-fluid analysis of an industrial facility. Let us empower the projects with state-of-the-art simulation technology.

Energy

Drive innovation, improve product yield, and enhance process safety by combining advanced process modeling, real-time process monitoring, and data-driven decision making.

A Smarter and More Connected Future

Digital Twin Solutions

Digital Twin technologies transform how businesses design, operate, and optimize their systems. By creating virtual replicas of physical assets, processes, or systems, we enable organizations to visualize, simulate, and improve their operations in real-time.

What We Offer

Our Digital Twin services are tailored to the unique needs of diverse industries, providing insights that empower smarter decisions.

Minimize downtime and maintenance costs by leveraging real-time data and predictive analytics to foresee equipment failures before they happen.

Enhance efficiency by simulating different scenarios, testing strategies, and implementing best practices with minimal risk to physical operations.

Continuously track asset performance with live data to ensure peak productivity, improved energy efficiency, and reduced operational expenses.

Offer immersive, risk-free environments for employee training or scenario planning, ensuring better preparedness and improved safety.